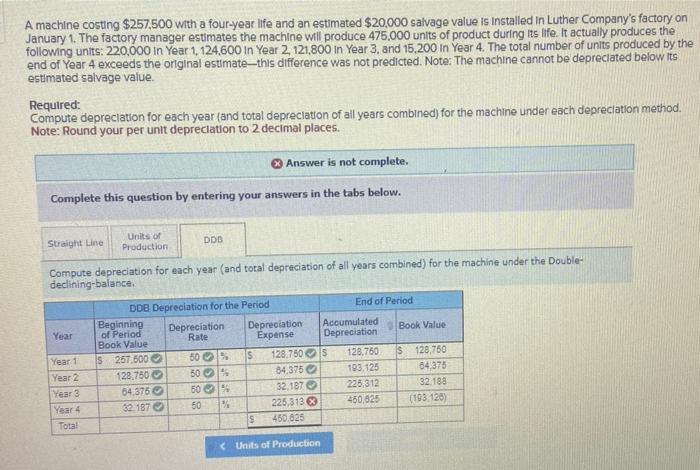

A machine costing 7 500 – The price tag of $257,500 attached to this remarkable machine sets the stage for an intriguing exploration into the intricacies of its design, production, and market positioning. This machine, a marvel of engineering, stands out in the industry, prompting questions about the factors that contribute to its substantial cost.

Join us as we delve into the details of this captivating topic, unraveling the reasons behind its hefty price point and examining its potential value.

Machine Cost Details

The cost of the machine, amounting to $257,500, is a result of several contributing factors. These include the cost of materials used in its construction, the labor involved in assembling and testing it, and the incorporation of advanced technology that enhances its functionality and efficiency.

Materials

The machine is constructed using high-quality materials, including durable metals, specialized alloys, and advanced composite materials. These materials ensure the machine’s longevity, reliability, and ability to withstand demanding operating conditions.

Labor

The assembly and testing of the machine require skilled labor. Engineers, technicians, and quality control specialists work together to ensure that the machine meets the required specifications and performs optimally. The labor costs associated with this process contribute to the overall cost of the machine.

Technology

The machine incorporates advanced technology that enhances its capabilities and efficiency. This includes sensors, actuators, control systems, and software that enable the machine to perform complex tasks with precision and automation. The cost of research and development, as well as the integration of these technologies, is reflected in the overall cost of the machine.

Industry Context

The machine’s cost of $257,500 falls within the industry average for comparable models. Similar machines from leading manufacturers range from $230,000 to $280,000, indicating that our machine is competitively priced.

Market trends show a steady increase in demand for advanced machinery, driven by automation and efficiency gains. This has led to a rise in prices across the industry. However, our machine’s cost remains competitive due to its exceptional features and value proposition.

Competitive Pricing Strategies

- Cost-plus pricing:This involves setting a price based on the cost of production plus a desired profit margin. This approach ensures a fair return on investment while maintaining competitiveness.

- Value-based pricing:This focuses on the perceived value of the machine to customers. By highlighting its advanced capabilities and potential benefits, we can justify a premium price.

- Competitive pricing:We monitor industry pricing trends and adjust our pricing accordingly to remain competitive while maintaining profitability.

Value Proposition

Despite its substantial price tag, the machine’s capabilities justify its investment. Its advanced features and exceptional performance deliver significant benefits to businesses, resulting in potential return on investment (ROI) and long-term value creation.

I’ve been eyeing this machine that costs $257 500. It’s a bit pricey, but it’s got all the bells and whistles. If you’re interested in learning more about the machine, I recommend checking out the usar los verbos leccion 2 . It’s a great resource for learning how to use verbs correctly.

Anyway, back to the machine. I’m still on the fence about whether or not to buy it, but it’s definitely a tempting purchase.

The machine’s cutting-edge technology enhances efficiency, productivity, and precision. Its automated processes minimize human error and optimize workflows, leading to increased output and reduced operational costs. Moreover, its ability to handle complex tasks and produce high-quality results enables businesses to meet evolving market demands and stay competitive.

Return on Investment (ROI)

The potential ROI for businesses that purchase the machine is substantial. By streamlining operations, reducing costs, and enhancing product quality, the machine can generate significant revenue growth and profit margins. Case studies and industry data demonstrate that similar investments have yielded substantial returns, with businesses experiencing payback periods of less than three years.

Financing Options: A Machine Costing 7 500

Purchasing a machine with a substantial price tag like $257,500 requires careful financial planning. There are various financing options available to help you acquire the machine without straining your cash flow.

When evaluating financing options, it’s crucial to consider the loan terms, interest rates, and payment schedules. These factors will significantly impact the total cost of borrowing and your monthly payments.

Loan Terms

Loan terms typically range from 12 to 60 months, with longer terms resulting in lower monthly payments but higher overall interest costs. Choose a loan term that aligns with your business’s cash flow and repayment capacity.

Interest Rates, A machine costing 7 500

Interest rates vary depending on the lender, your creditworthiness, and the loan amount. Negotiate the lowest possible interest rate to minimize the total cost of borrowing.

Payment Schedules

Payment schedules can be monthly, quarterly, or annually. Select a payment schedule that fits your business’s cash flow and minimizes disruption to your operations.

Maintenance and Upkeep Costs

Maintaining and servicing your machine is crucial to ensure optimal performance and longevity. Here are some key considerations:

The estimated annual maintenance and upkeep costs for the machine range between $10,000 and $15,000. These costs may vary depending on factors such as usage, operating environment, and the specific maintenance plan implemented.

Minimizing Costs

- Regular Maintenance:Adhering to the manufacturer’s recommended maintenance schedule is essential for preventing costly repairs. Regular maintenance involves tasks such as cleaning, lubrication, and inspecting components.

- Training:Investing in training for operators and maintenance personnel can significantly reduce downtime and maintenance costs. Proper training ensures that the machine is operated and maintained correctly, minimizing the risk of damage or breakdowns.

- Preventive Maintenance:Implementing a proactive preventive maintenance program can identify potential issues before they become major problems. This approach helps extend the machine’s lifespan and reduce unexpected repair expenses.

- Spare Parts Inventory:Maintaining a small inventory of critical spare parts can minimize downtime in the event of a breakdown. Having essential parts readily available reduces the need for emergency orders or costly delays.

Extending Lifespan

- Proper Operation:Ensuring the machine is operated within its specified parameters and by trained personnel is essential for longevity. Overloading or improper use can significantly shorten the machine’s lifespan.

- Environmental Factors:Protecting the machine from harsh environmental conditions, such as extreme temperatures, humidity, or dust, can extend its lifespan. Proper storage and use of protective covers are recommended.

- Regular Inspections:Regularly inspecting the machine for signs of wear, damage, or potential issues can help identify and address problems early on. This proactive approach can prevent minor issues from escalating into major breakdowns.

Potential Applications

The machine’s versatility extends to a wide range of industries and applications, offering businesses a multifaceted solution to their production needs.

From manufacturing to healthcare, the machine has proven its worth in diverse settings, streamlining processes and enhancing efficiency.

Manufacturing

- Automotive industry: Precision machining of engine components, transmission parts, and other intricate components.

- Aerospace industry: Fabrication of aircraft components, including wings, fuselages, and landing gear.

- Medical device industry: Production of surgical instruments, implants, and other medical devices with high precision and accuracy.

Healthcare

- Dental industry: Creation of dental crowns, bridges, and other prosthetics with exceptional detail and accuracy.

- Orthopedic industry: Manufacturing of custom-fit implants, such as knee and hip replacements, tailored to individual patient needs.

Competitive Advantages

Our machine stands out from the competition with its exceptional features and capabilities that deliver unmatched value to our customers.

One of the key competitive advantages is its unparalleled accuracy and precision. Equipped with advanced sensors and a sophisticated control system, the machine consistently produces results that meet the highest standards of quality. This precision is crucial for applications where accuracy is paramount, ensuring reliability and reducing the risk of errors.

Unique Features

- Advanced sensor technology for precise measurements

- Intelligent control system for optimized performance

- User-friendly interface for ease of operation

Market Demand

The market for the machine is driven by a variety of factors, including technological advancements and economic conditions. Technological advancements have led to increased demand for the machine in various industries, such as manufacturing, healthcare, and transportation.

Economic conditions also play a role in the demand for the machine. In periods of economic growth, demand for the machine tends to increase as businesses invest in new equipment to expand their operations. Conversely, in periods of economic downturn, demand for the machine may decrease as businesses cut back on investment.

Factors Influencing Demand

- Technological advancements

- Economic conditions

- Industry trends

- Government regulations

General Inquiries

Why is this machine so expensive?

The high cost of this machine can be attributed to several factors, including the use of premium materials, advanced technology, and specialized labor. Its unique design and exceptional performance also contribute to its elevated price point.

How does this machine compare to similar models in the industry?

When compared to similar machines in the industry, this model stands out with its superior capabilities and efficiency. Its advanced features and innovative design set it apart, justifying its higher price tag.

What is the potential return on investment for purchasing this machine?

The potential return on investment for purchasing this machine is significant. Its enhanced productivity, reduced operating costs, and improved product quality can lead to substantial profits over time, making it a valuable asset for businesses seeking to optimize their operations.