Which of the following are included in raw materials inventory – The realm of raw materials inventory encompasses a vast array of materials that serve as the building blocks for countless products. Delving into the intricacies of which materials qualify for inclusion within this inventory, this exploration unveils the significance of tracking both direct and indirect raw materials, while also examining the techniques employed for effective inventory management.

From the essential role of direct raw materials in the production process to the often overlooked yet crucial contribution of indirect raw materials, this discourse sheds light on the comprehensive nature of raw materials inventory. Moreover, it delves into the intricacies of inventory management techniques, contrasting their advantages and disadvantages to empower informed decision-making.

Raw Materials Inventory

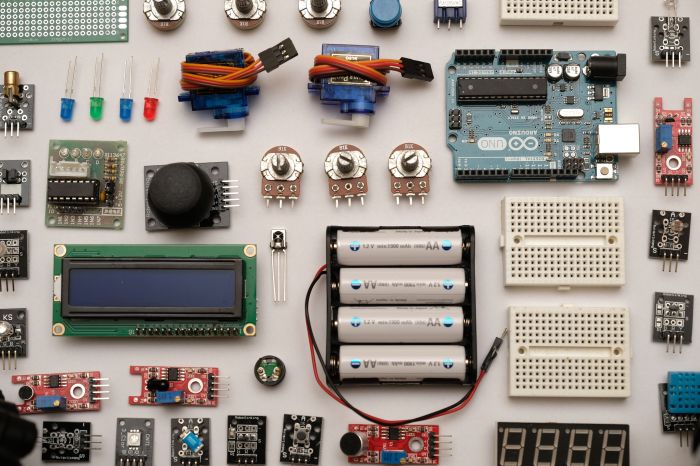

Raw materials inventory refers to the physical goods and components that a company holds for the purpose of producing finished goods. These materials are essential for the manufacturing process and can be classified into two main categories: direct and indirect raw materials.

Direct Raw Materials

Direct raw materials are those that can be directly traced to the finished product. They are the primary components of the product and typically constitute the largest portion of the raw materials inventory.

- Examples of direct raw materials include:

- Wood for furniture

- Fabric for clothing

- Steel for automobiles

It is crucial to track direct raw materials accurately to ensure that there is sufficient supply for production and to avoid disruptions in the manufacturing process.

Indirect Raw Materials

Indirect raw materials are those that are used in the production process but are not directly traceable to the finished product. They are typically used in smaller quantities and may include:

- Lubricants for machinery

- Cleaning supplies

- Packaging materials

Indirect raw materials play a vital role in ensuring the smooth functioning of the production process and maintaining the quality of the finished goods.

Inventory Management Techniques

| Inventory Management Technique | Advantages | Disadvantages |

|---|---|---|

| First-in, First-out (FIFO) | – Simple to implement

|

– May not reflect the actual cost of goods sold

|

| Last-in, First-out (LIFO) | – Assumes that newer inventory is used first

|

– May not reflect the actual cost of goods sold

|

| Weighted Average | – Provides a more accurate cost of goods sold

|

– Can be complex to implement

|

Raw Materials Storage and Handling, Which of the following are included in raw materials inventory

Proper storage and handling of raw materials are essential to prevent damage, loss, and contamination. Best practices include:

- Storing materials in a clean, dry, and temperature-controlled environment

- Using proper packaging and labeling to protect materials from damage

- Rotating inventory to ensure that older materials are used first

- Regularly inspecting materials for damage or spoilage

Common storage and handling challenges include:

- Space constraints

- Temperature and humidity control

- Pest control

- Proper handling of hazardous materials

Raw Materials Inventory Valuation

| Inventory Valuation Method | Steps Involved |

|---|---|

| Specific Identification | – Identify the cost of each specific unit of inventory

|

| First-in, First-out (FIFO) | – Assume that the first units purchased are the first units sold

|

| Last-in, First-out (LIFO) | – Assume that the last units purchased are the first units sold

|

| Weighted Average | – Calculate the average cost of all units in inventory

|

Essential Questionnaire: Which Of The Following Are Included In Raw Materials Inventory

What constitutes direct raw materials?

Direct raw materials are those that can be directly attributed to the production of a finished good, such as the wood used in furniture or the fabric used in clothing.

How do indirect raw materials differ from direct raw materials?

Indirect raw materials are those that are used in the production process but cannot be directly attributed to a specific finished good, such as lubricants or cleaning supplies.

What is the importance of inventory management for raw materials?

Inventory management helps businesses track the quantity and value of raw materials on hand, ensuring that there is sufficient supply to meet production needs while minimizing waste and spoilage.